NdFeB Magnets Specifications, Grades, Magnetization & Custom Engineering

Learn how different materials, magnetization patterns, coatings, and tolerance controls impact your application—backed by our global engineering experience and China’s manufacturing capabilities.

We also offer comprehensive coating options — tailored to your operating environment.

Achieve stronger pull force with optimized magnetic circuit design.

Ideal for applications requiring high efficiency and reduced material cost.

NdFeB Magnet Performance Table

• N Standard temperature, typical max. operating temp ~80 °C.

• M Medium temperature, up to ~100 °C.

• H / SH High-temperature grades, typically 120–150 °C.

• UH / EH / TH Ultra high-temperature grades, typically 180–230 °C and above.

Tip: Click column headers to sort. , or search by grade/keyword.

| Grade | Series | Br [T] | Br [kGs] | HcJ [kA/m] | HcJ [kOe] | HcB [kA/m] | HcB [kOe] | (BH)max [kJ/m³] | Max Operating Temp [°C] | α(Br) [%/°C] | β(HcJ) [%/°C] |

|---|

Other Material Properties

(reference values)

| Parameter | Unit | Reference Value | Parameter | Unit | Reference Value |

|---|---|---|---|---|---|

| Curie Temperature | °C | 310 ~ 400 | Thermal Conductivity | W/m·°C | 8 ~ 10 |

| Density | g/cm³ | 7.4 ~ 7.7 | Young’s Modulus | GPa | 150 ~ 200 |

| Vickers Hardness | HV | 500 ~ 700 | Electrical Resistivity | C∥ μΩ·m | 1.4 ~ 1.6 |

| Recoil Permeability | — | 1.02 ~ 1.08 | C⊥ μΩ·m | 1.2 ~ 1.4 | |

| Compressive Strength | MPa | 1000 ~ 1100 | Coefficient of Thermal Expansion | C∥ 10⁻⁶/°C | 4 ~ 9 |

| Flexural Strength | MPa | 150 ~ 400 | C⊥ 10⁻⁶/°C | −2 ~ 0 |

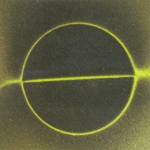

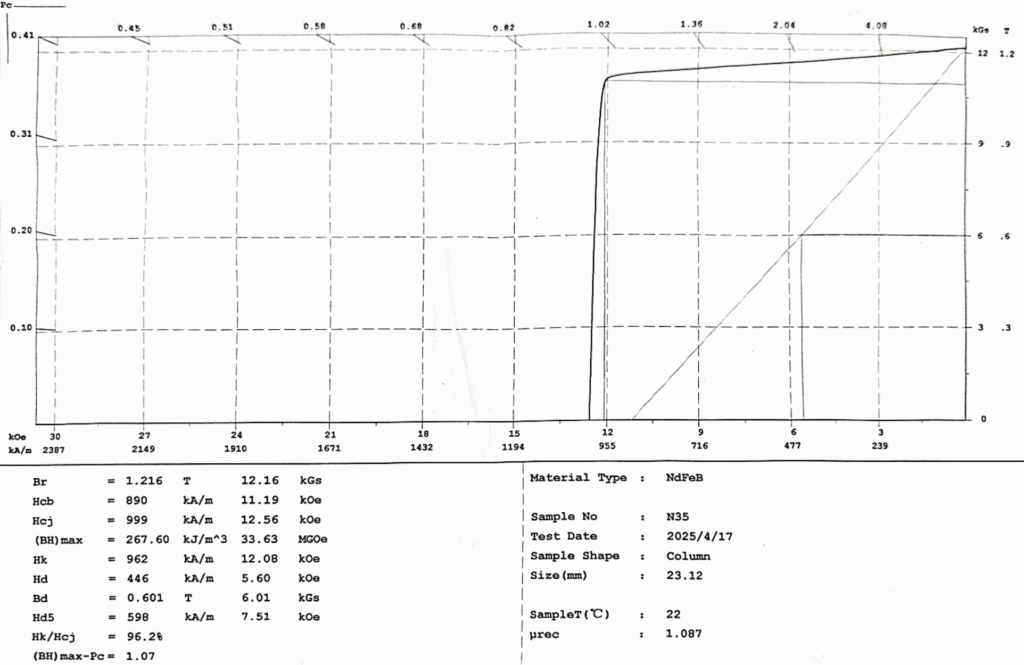

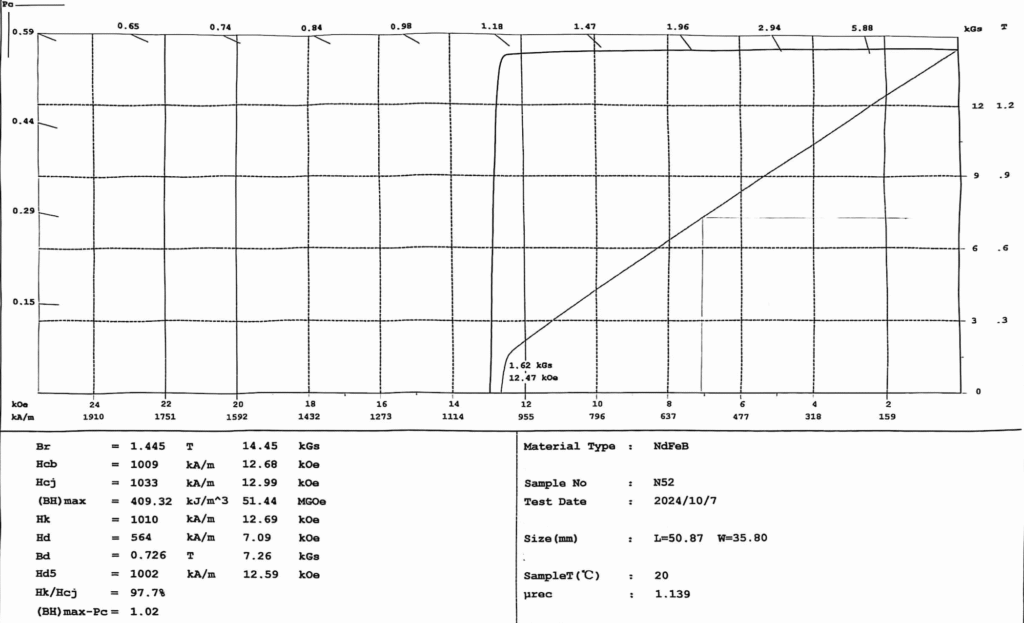

B-H Curve

Our NdFeB Products by Automatic Hysteresisgraph AMT-4

Material Type: NdFeB

Grade: N35

Sample Shape: Column

Size (mm): Diameter = 23.12

Sample Temperature: 22°C

μrec: 1.087

Magnetic Properties – N35

| Br | 1.216 T | 12.16 kGs |

| Hcb | 890 kA/m | 11.19 kOe |

| Hcj | 999 kA/m | 12.56 kOe |

| (BH)max | 267.60 kJ/m³ | 33.63 MGOe |

| Hk | 962 kA/m | 12.08 kOe |

| Hd | 446 kA/m | 5.60 kOe |

| Bd | 0.601 T | 6.01 kGs |

| Hd5 | 598 kA/m | 7.51 kOe |

| Hk/Hcj Ratio | 96.2% | |

| (BH)max-Pc | 1.07 | |

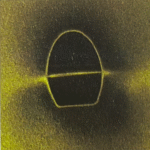

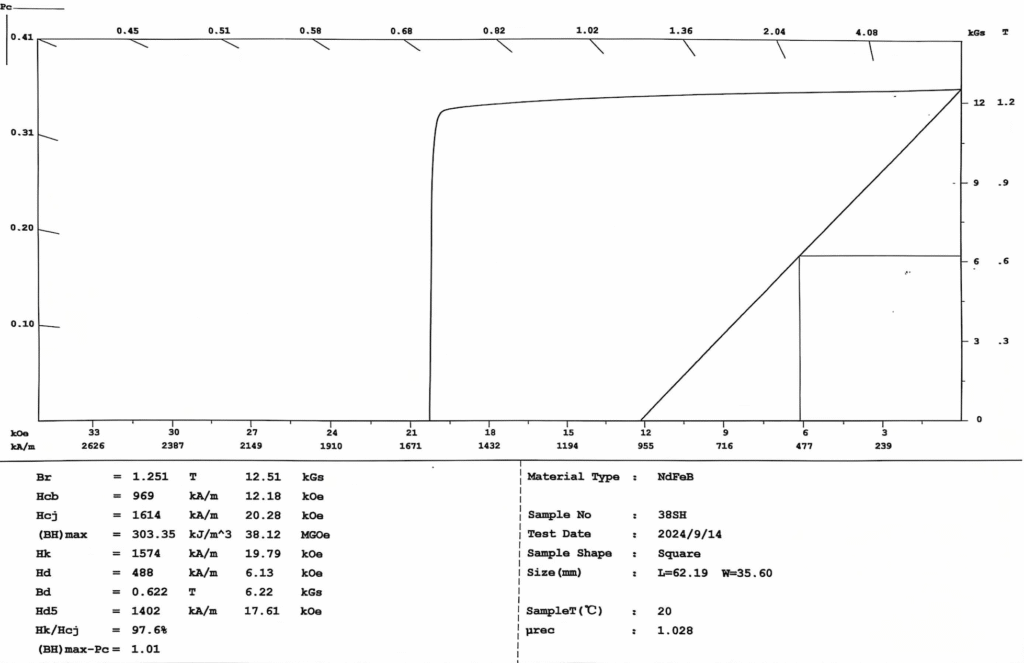

Material Type: NdFeB

Grade: 38SH

Sample Shape: Square

Size (mm): L 62.19 × W 35.60

Sample Temperature: 20°C

μrec: 1.028

Magnetic Properties – 38 HS

| Br | 1.251 T | 12.51 kGs |

| Hcb | 969 kA/m | 12.18 kOe |

| Hcj | 1614 kA/m | 20.28 kOe |

| (BH)max | 303.35 kJ/m³ | 38.12 MGOe |

| Hk | 1574 kA/m | 19.79 kOe |

| Hd | 488 kA/m | 6.13 kOe |

| Bd | 0.622 T | 6.22 kGs |

| Hd5 | 1402 kA/m | 17.61 kOe |

| Hk/Hcj Ratio | 97.6% | |

| (BH)max-Pc | 1.01 | |

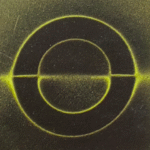

Material Type: NdFeB

Grade: N52

Size (mm): L 50.87 × W 35.80

Sample Temperature: 20°C

μrec: 1.139

Magnetic Properties – N52

| Br | 1.445 T | 14.45 kGs |

| Hcb | 1009 kA/m | 12.68 kOe |

| Hcj | 1033 kA/m | 12.99 kOe |

| (BH)max | 409.32 kJ/m³ | 51.44 MGOe |

| Hk | 1010 kA/m | 12.69 kOe |

| Hd | 564 kA/m | 7.09 kOe |

| Bd | 0.726 T | 7.26 kGs |

| Hd5 | 1002 kA/m | 12.59 kOe |

| Hk/Hcj Ratio | 97.7% | |

| (BH)max-Pc | 1.02 | |

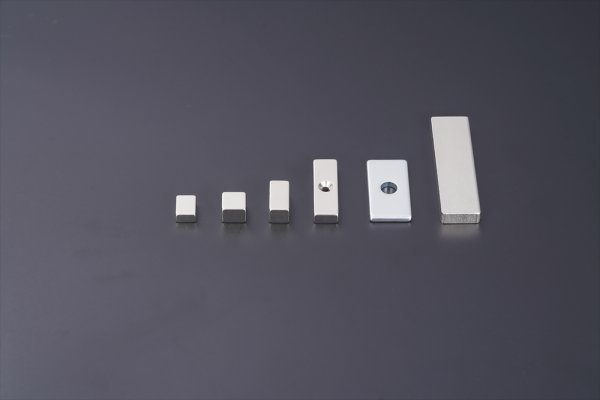

Produts Shapes

We offer shapes customization: block, ring, disc, arc...

Not your ideal pattern?

Tell us your magnet requirements — our engineers will respond within 24 hours

FAQs

A selection of our precision sintered NdFeB magnets in various applications.

Can magnets be manufactured in irregular shapes?

Yes. Custom magnets can be manufactured in a wide range of complex shapes, including arc, segment, stepped, and perforated designs.

Specialized equipment such as 5-axis CNC machines, EDM, and custom fixtures is used to achieve accurate machining.

The manufacturing process is adjusted based on shape complexity to ensure the magnets do not crack, maintain precise dimensions, and meet specific design requirements.

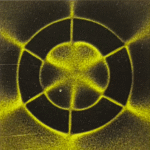

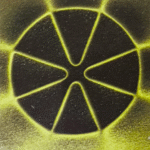

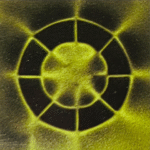

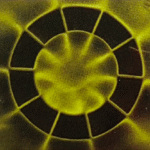

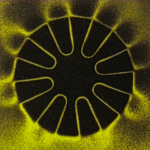

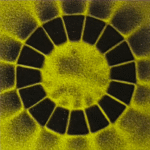

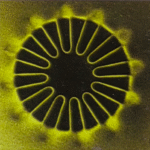

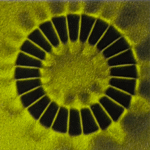

Can custom magnets be supplied with multipole magnetization?

Yes. Custom magnets can be supplied with multipole magnetization to support applications requiring complex magnetic fields.

Alternating N/S poles (such as 4, 8, 16 poles or more) are created using custom-designed magnetizing fixtures based on pole count, pole pitch, and magnet geometry.

High-precision magnetizing equipment ensures uniform magnetic strength and accurate pole positioning.

Multipole magnets are widely used in precision motors, sensors, and magnetic encoders, where they help improve control accuracy and overall system performance.

Can the magnetization direction be customized?

Yes. We can customize the magnetization direction to meet specific application requirements.

Common options include axial, radial, and multipole magnetization.

Specialized magnetizing equipment and fixtures ensure correct N/S pole orientation and a consistent magnetic field direction.

Customized magnetization allows better integration with surrounding components and improves performance in applications such as motors and sensors.

How is quality controlled in our magnet manufacturing?

Is small-batch or prototype production available for custom magnets?

How is the logistics and shipping process for magnets?

For standard magnet grades that do not involve regulated elements, shipment can be arranged quickly after routine inspection.

However, due to government regulations related to certain rare earth materials, some magnet grades may require additional approval, which can result in a longer lead time.

Please contact us with your specific grade and application requirements, so we can provide an estimated shipping timeline.